Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for factory Outlets for Fiberglass Combo Core Mat, With the development of society and economy, our company will keep a tenet of “Focus on trust, quality the first”, moreover, we expect to create a glorious future with every customer.

Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for China fiberglass combo mat and fiberglass woven fabric combo mat, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

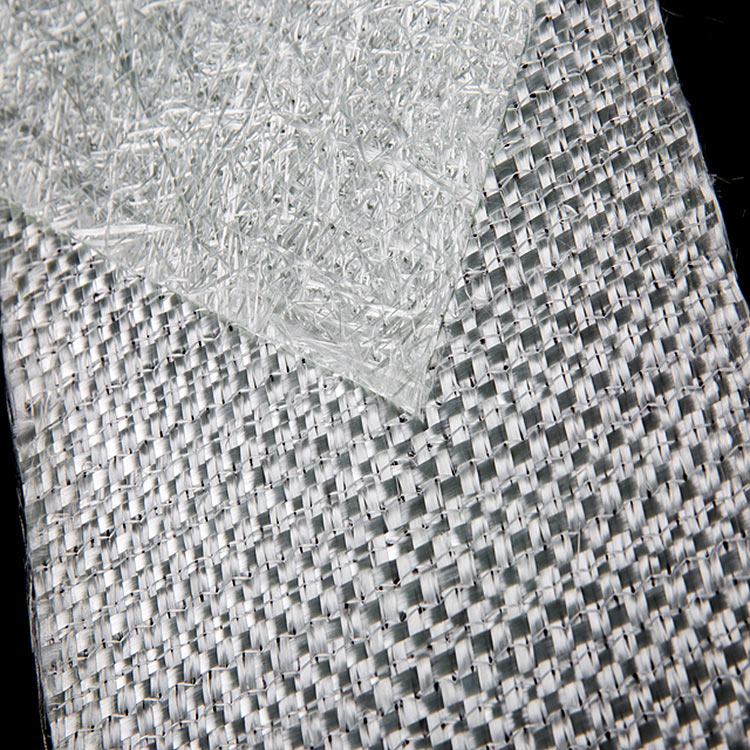

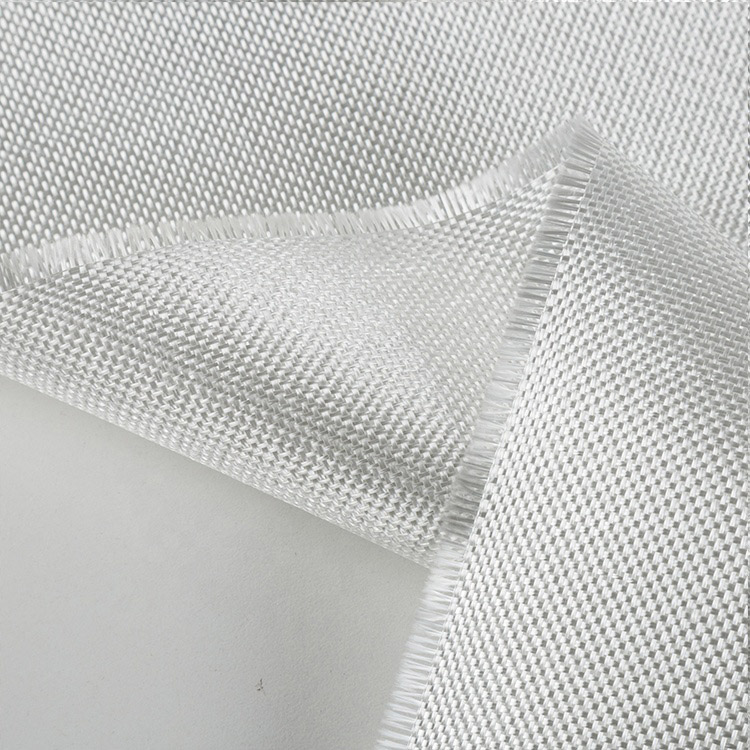

Weaving Process

The Combo Mat is made by cutting the continuous roving to certain length and undirectionally and uniformly spread on the woven roving , PP knitted mat, polyester mat and knitted together by threads. It’s compatible with UP, Vinyl ester, phenolic and epoxy resin.

Product Specifications

| Product Number |

Glass |

Warp/Weft Linear Denslty Tex |

Warp/Weft Denslty Ends/cm |

Woven Roving/Basic Material

(g/㎡) |

Choppde strands (g/㎡) |

Overall Density(g/㎡) |

| EMK400/200 |

E |

2400 |

E7 |

400 |

200 |

600 |

| EMK600/300 |

E |

2400 |

E7 |

600 |

300 |

900 |

| EMK600/450 |

E |

2400 |

E7 |

600 |

450 |

1050 |

| EMK800/225 |

E |

2400 |

E7 |

800 |

225 |

1025 |

| EMK800/450 |

E |

2400 |

E7 |

800 |

450 |

1250 |

| EMK800/300 |

E |

2400 |

E7 |

800 |

300 |

1100 |

| EMK300/PP180/M300 |

E |

2400 |

E7 |

180 |

300×2 |

780 |

| EMK300/TF35 |

E |

2400 |

E7 |

35 |

300 |

335 |

Application

It’s widely used in FRP Pultrusion, hand lay-up, RTM process to make FRP boat hulls, car body, Panel and Sheets, cooling Parts, car doors and profiles, radome etc.

Storage

The product should be stored in a cool, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15℃ to 35℃ and 35% to 65% respectively. Please keep the product in its original packaging before being used, avoiding moisture absorption.Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for factory Outlets for Fiberglass Combo Core Mat, With the development of society and economy, our company will keep a tenet of “Focus on trust, quality the first”, moreover, we expect to create a glorious future with every customer.

factory Outlets for China fiberglass combo mat and fiberglass woven fabric combo mat, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Previous:

Hot-selling E Glass Fiberglass Fabric Stitched Mat

Next:

factory low price Fiberglass 4800tex Filament Winding Roving for Rebar