understand

Need A Solution?Contact Us For Best

Would you like to know

more, We can give you

the answer

contact us

Contact us anytime, anywhere we've been- Phone: +86 15283895376

- WhatsApp: +86 15283895376

- Address: Group 1, Taiping village, Wan'an town, Luojiang district, Deyang city, Sichuan province,China.

- E-mail: yaoshengfiberglass@gmail.com

© Copyright - 2021-2022 : All Rights Reserved.

Hot Products - Sitemap - AMP Mobile

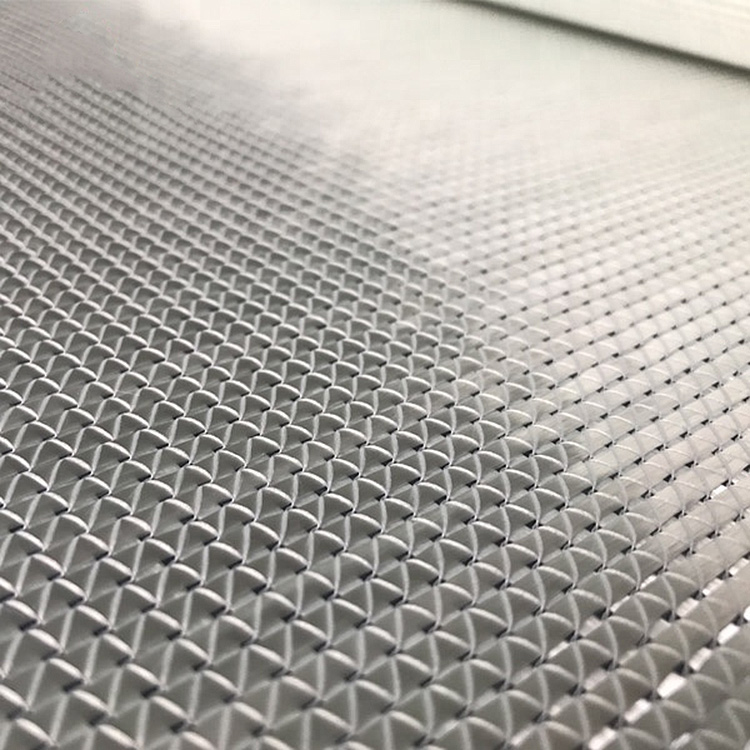

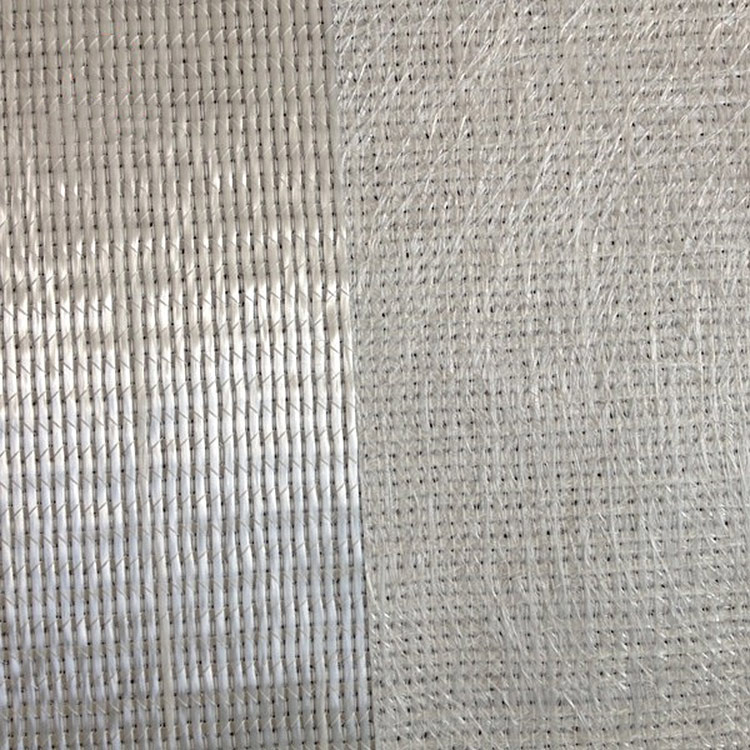

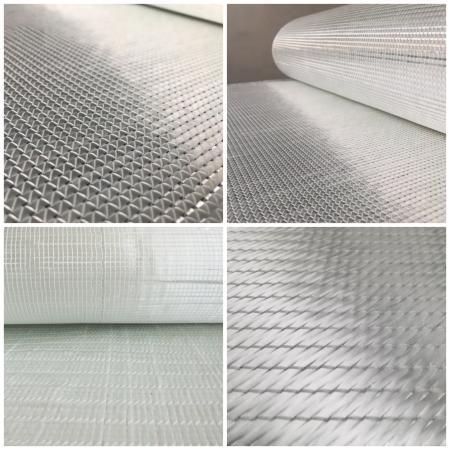

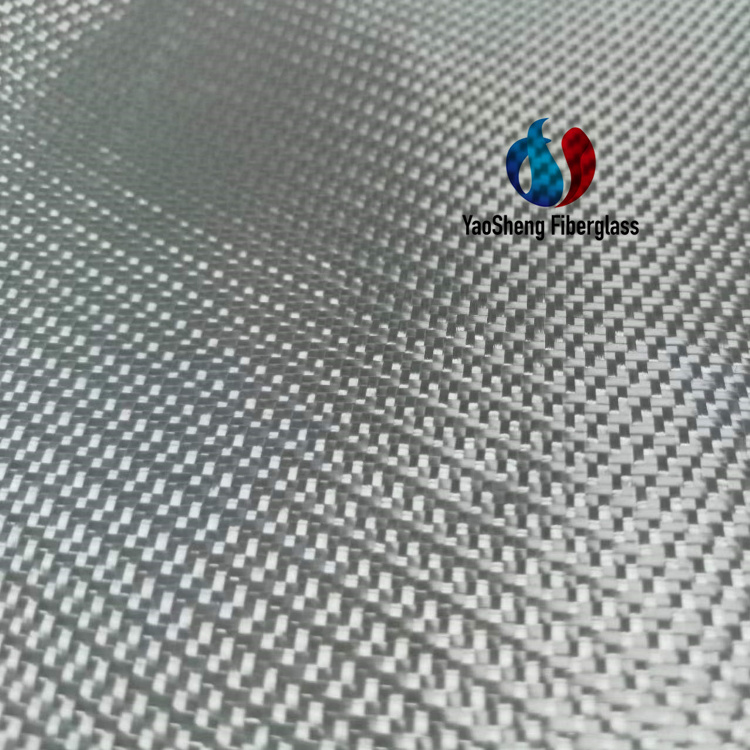

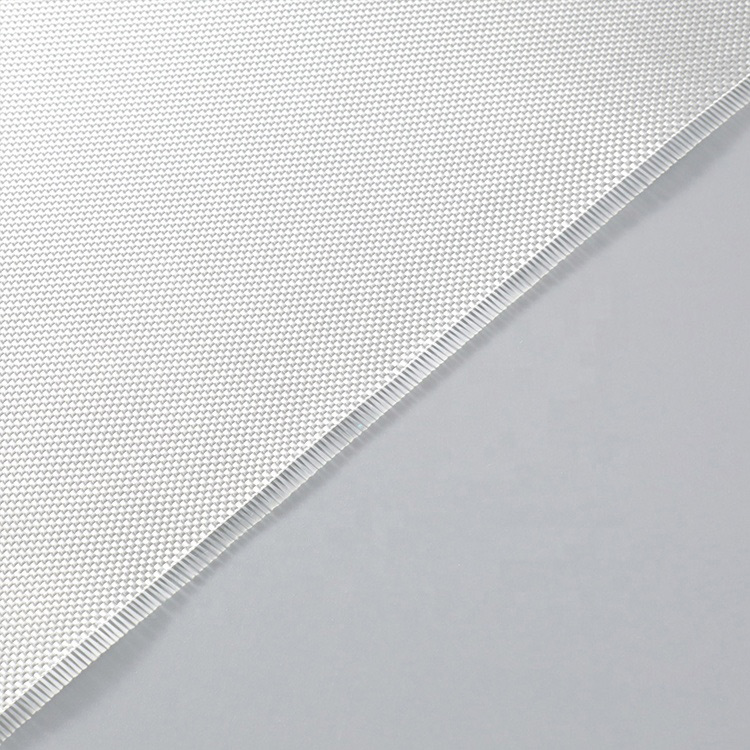

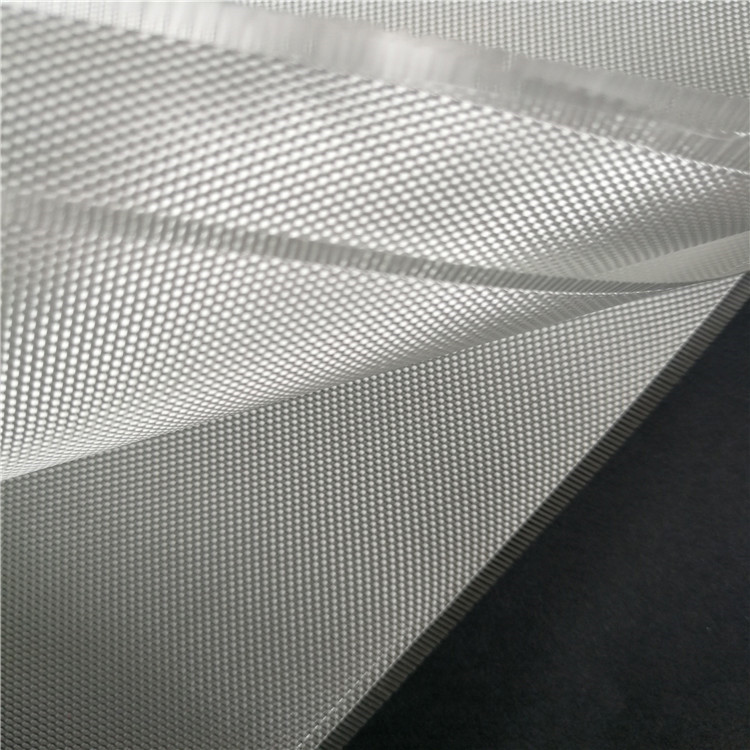

Glass Fiber Roll, E Glass Roving, 800g Ewr E-Glass Woven Roving Plain, e glass woven roving, Fiberglass Cloth Thickness, Frp Panel E-Glass Fiber Cloth,

Glass Fiber Roll, E Glass Roving, 800g Ewr E-Glass Woven Roving Plain, e glass woven roving, Fiberglass Cloth Thickness, Frp Panel E-Glass Fiber Cloth,